Custom Plastic Window & Patio Door Parts

Custom Plastic Parts For Windows & Patio Doors

Custom plastic injection molding plays a key role in the window and door industry, enabling the production of a broad range of durable and aesthetically pleasing components. Its flexibility, precision, and consistency make it an invaluable tool in meeting the today’s evolving needs.

Custom plastic injection molding is a cornerstone of the window and door industry, providing the means to produce durable, precise, and customizable components. Whether it’s a frame that can withstand harsh weather, a lock that ensures security, or a thermal break that improves energy efficiency, injection molding provides the solutions.

A primary use of custom injection molding in this industry is in the creation of window and door frames. These components need to be strong, weather-resistant, and able to maintain their appearance and functionality over time. Injection molding allows for the use of high-performance plastics that can meet these demands, while also enabling intricate, custom designs and finishes that mimic traditional materials like wood or metal, but with reduced maintenance needs.

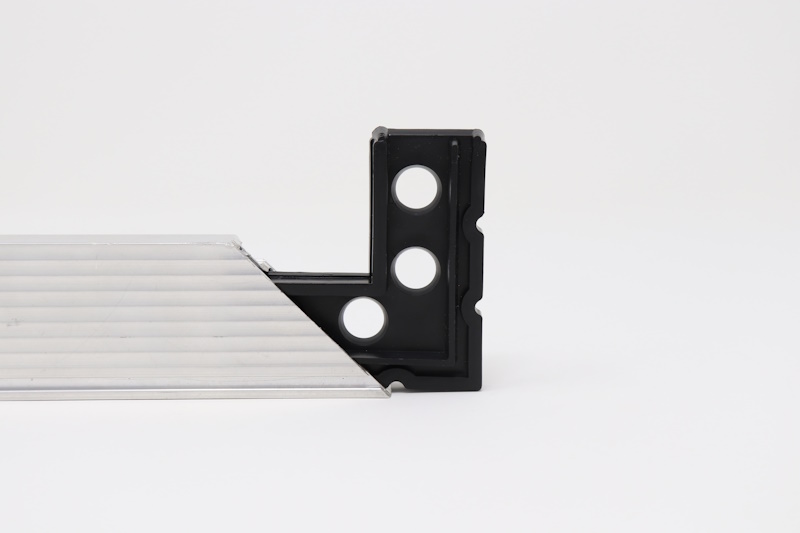

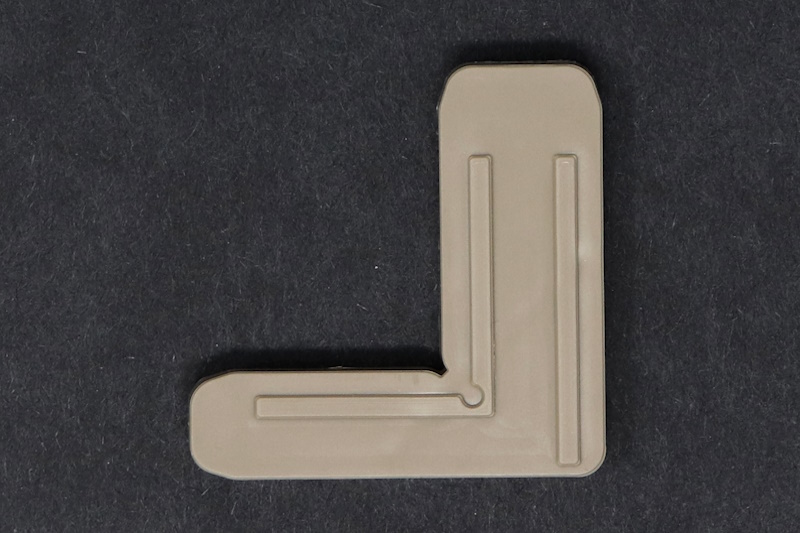

Beyond frames, custom plastic injection molding is also used to manufacture a wide variety of hardware and accessory parts for doors and windows. These include handles, locks, hinges, seals, corner keys, corner track keys, casement lip screen frame corners, come-along window parts, plastic patio door encasement parts, and spreader clip patio door parts, just to name a few. The ability to create complex shapes with high precision makes injection molding ideal for these components.

Our custom plastic injection molded window and door items are made from start to finish in-house, in our Peterborough, Ontario facility. We create the artwork and design, implement the engineering and CAD programming, produce the dies and molds, and take care of all the details. You only have to deal with one company—no third parties required.

Full and Fast Service

- Specializing in fast turnaround – days not weeks, 24X7 operation when required

- Fast prototyping of custom molds using CAD, molds are milled with in-house CNC machinery

- Resins include polypropylene, polyethylene, and polystyrene; standard and custom colors

- Custom branding, hot stamping and printing

- Flow-wrapping of individual products

Sample Products

(Click images for larger view)