Plastic Injection Molding Industry

Custom Plastic Injection Molding Industry

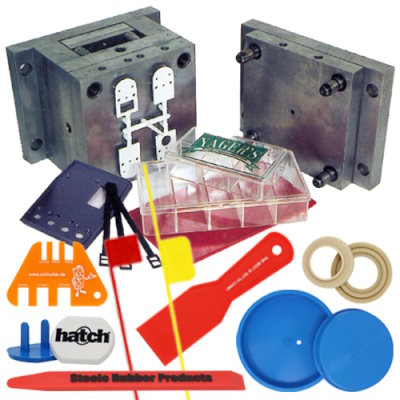

The custom plastic injection molding industry plays a critical role in manufacturing across diverse sectors due to its flexibility, efficiency, and precision. It’s a process where plastic is melted and then injected into a mold under high pressure. Once cooled, the product takes the shape of the mold, which can be as simple or as complex as necessary. This wide range of possibilities has made custom plastic injection molding a cornerstone of various industries, from medical to automotive, consumer electronics to packaging, and beyond.

What sets the custom plastic injection molding industry apart is its capacity for customization. Each mold is created to meet a specific set of requirements, which allows businesses to produce unique, tailored products, components, or parts. This is essential for sectors that need high-precision parts, such as the aerospace or medical industries, or those that want distinctive, branded items, like the promotional or consumer goods sectors.

Our products are BPA-free, recyclable and FDA-approved.

Full and Fast Service

- Specializing in fast turnaround – days not weeks, 24X7 operation when required

- Fast prototyping of custom molds using CAD, molds are milled with in-house CNC machinery

- Resins include polypropylene, polyethylene, and polystyrene; standard and custom colors

- Custom branding, hot stamping and printing

- Flow-wrapping of individual products