Industrial Components & Applications

Custom Plastic Injection Molded Components for Industrial Applications

Industrial items often require components that are strong, durable, resistant to wear and tear, and are able to withstand various environmental conditions. Custom plastic injection molding is an ideal manufacturing process for these types of industrial components as it offers the ability to use a wide range of plastic materials, including high-performance thermoplastics that offer enhanced strength, temperature resistance, and chemical resistance.

In addition to machine parts, custom injection molding is also used for a variety of other industrial uses, including storage bins, safety equipment, and tool handles. The ability to produce custom designs and sizes is particularly advantageous in industrial and manufacturing settings where precise, custom needs and configurations often arise.

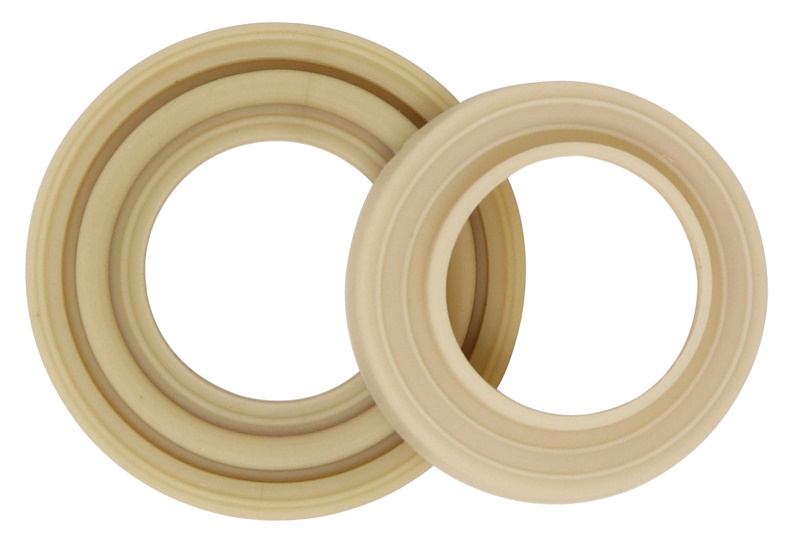

For over 45 years, we have produced a wide variety of industrial items such as: caps and plugs, floor tile measuring gauges, putty knives, putty scrapers, outlet plug covers, plastic & rubber gaskets, containers of all shapes and sizes, custom squeegees, vehicle trim tools, measuring calipers, station and bait markers, and empty chamber indicator flags (ECIs).

Our custom plastic injection molded industrial elements are made from start to finish, in-house in our Peterborough, Ontario facility. We create the artwork and design, implement the engineering and CAD programming, produce the dies and molds, and take care of all the details. You only have to deal with one company—no third parties required.

Full and Fast Service

- Specializing in fast turnaround – days not weeks, 24X7 operation when required

- Fast prototyping of custom molds using CAD, molds are milled with in-house CNC machinery

- Resins include polypropylene, polyethylene, and polystyrene; standard and custom colors

- Custom branding, hot stamping and printing

- Flow-wrapping of individual products

Sample Products

(Click images for larger view)